In this article, the authors will demonstrate how MFC can improve the resistance to viscosity loss upon tinting without sacrificing the flow/leveling properties of the coating.

By Otto Soidinsalo, Harrison C. Gallantree-Smith, and Scott Mouw Borregaard AS

Associative thickeners are commonly used to thicken water-based coatings. Their mechanism of action is based on the hydrophobic interaction between the hydrophobic polymer groups as well as with the surface of the binder latex particles. It is commonly known that associative thickener-based formulations are prone to viscosity loss upon tinting due to the surfactants present in the tinting systems, leading to poorer sag resistance.

In this work, the effect of an insoluble microfibrillated cellulose (MFC) was studied on the prevention of viscosity loss on tinting with a deep tone base, formulated with two different hydrophobically modified polyurethane associative thickeners (HEURs), combined with a non-associative MFC thickener. The formulations were evaluated in terms of rheology, viscosity, sag resistance, flow/leveling, and gloss.

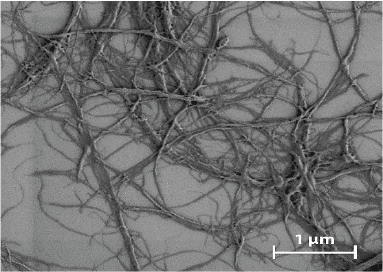

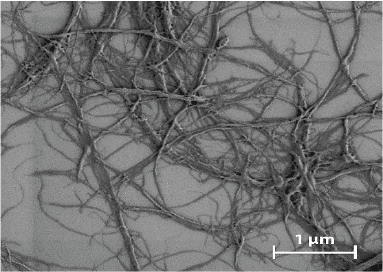

FIGURE 1 Scanning electron microscope image of MFC.

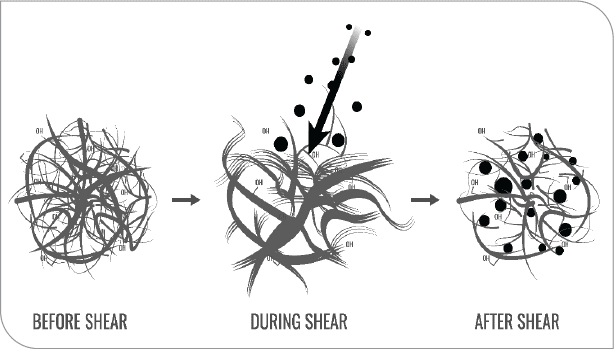

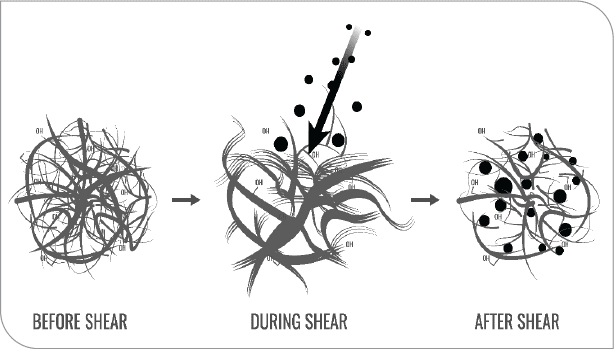

The compatibility and rheological behavior of MFC has previously been studied in water based acrylic and epoxy systems. The results from these studies showed that MFC dispersed very well into the resins and showed good compatibility. In addition, the viscosity and sag resistance increased with increasing concentration of MFC. Furthermore, the dispersions were heat stable in terms of sedimentation and retention of rheological properties. An example of the compatibility and stabilization effects of the fibrils is shown in Figure 2. The interaction of the OH-groups, via hydrogen bonding, on the surface of the entangled fibrils and the components (before shear) allows the increased stability of the formulation. Under shear forces (during shear) the disruption breaks the hydrogen bonding between the fibrils and OH-groups with the other components. Introduction of new components, such as the binder, interact with the open structure of the fibrillar network. Once shearing has stopped (after shear) the OH-groups and fibrils envelop the binder along with the original components, in-turn reforming the hydrogen bonding, allowing for increased stability of the formulation as well as increased compatibility.

FIGURE 2 Effect of shearing the microfibrillar network and the interaction with additional components (black dots) before, during and after shear.

Materials and Methods

Commercially available MFC was used in this study (manufactured by Borregaard AS) containing 10 wt % MFC in water. The following universal colorants were used for tinting: Lamp Black, Red Iron Oxide, and Phthalo Blue (8 oz/gal). Sag resistance was determined according to ASTM D4440 by using byko-chart 2852 and a LENETA Anti-Sag Meter “ASM-4 MEDIUM-RANGE” (4 mils (100 μm) – 24 mils (600 μm)); flow/leveling was determined according to ASTM D4062. The rheology was measured with an Anton Paar rheometer using a bob and cup measuring geometry.

Results and Discussion

Effect of MFC on the Rheology of an Acrylic Binder

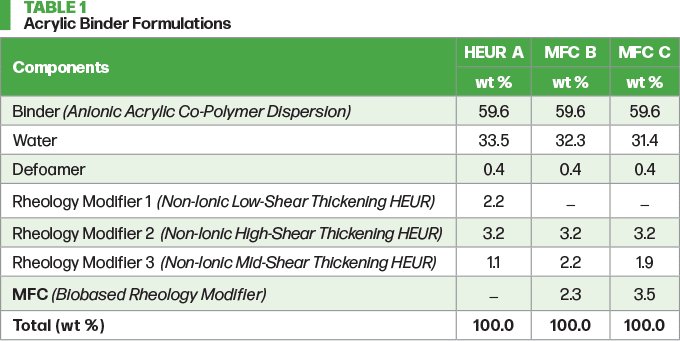

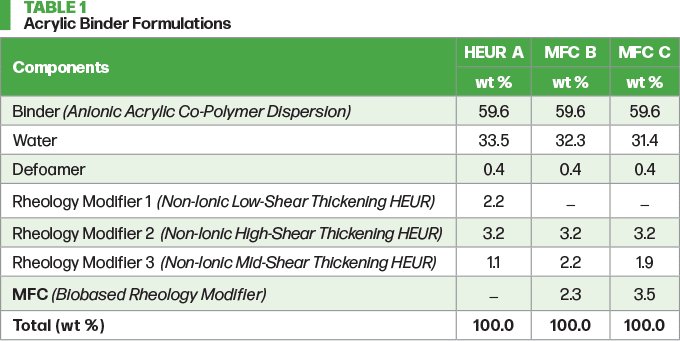

A simplified binder formulation was first used for studying the impact of MFC on the viscosity after tinting of an acrylic waterborne system (Table 1). The formulation was based on an anionic dispersion of an acrylic copolymer containing Rheology Modifier 1, a HEUR for low-shear viscosity adjustment.

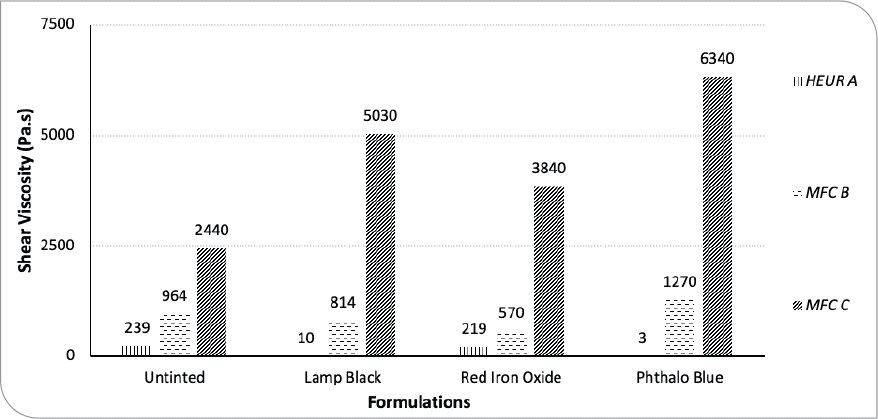

The strong impact of MFC to the low-shear viscosity of the formulations can be seen from Figure 3. Before tinting, the low-shear viscosity of the HEUR A formulation is 239 Pa.s, whereas the viscosity of the MFC B formulation is 964 Pa.s. After tinting, all lowshear viscosities of the HEUR-based systems decrease, most noticeably for the Lamp Black and Phthalo Blue formulations. In the case of both the MFC formulations (B and C), the low-shear viscosities increase dramatically when compared to the HEUR-based formulations both before and after tinting with all the tested universal colorants. Regarding the MFC C formulation, the low-shear viscosities actually have a large increase when a universal colorant is introduced, most notably with Phthalo Blue (2440 Pa.s. vs. 6340 Pa.s).

FIGURE 3 Low-shear viscosities for untinted and tinted (Lamp Black, Red Iron Oxide, and Phthalo Blue) formulations after 24 hours.

This noticeable increase in viscosity with MFC might be due to two reasons. Firstly, the physical entanglement of the nanosize fibrils and hydrogen bonding between the hydroxyl groups of MFC and hydrogen bonding compounds in the formulation are aiding the thickening effect. Secondly, the universal colorants typically contain glycol and glycol ethers, which are also known to strengthen the network of MFC. Based on these two reasons, the addition of MFC into the formulations positively impacts the lowshear viscosity on tinting, as seen especially with the MFC C formulations (Figure 3).

Continue reading in the July-August digital issue of CoatingsTech