Graphene as a two-dimensional nanomaterial has been extensively researched as a new additive to improve barrier performance, reduce corrosion and extend service life in protective coatings. Previous results have demonstrated significant uplifts in anticorrosive performance in solvent-based coatings using graphene nanoplatelets (GNPs), presenting new opportunities for improved protective coatings with extended service life.

However, water-based coating development remains a key focus for industry formulators where there is an ongoing effort to reduce the release of volatile organics and achieve comparable anticorrosion performance to that seen in solvent-based systems.

To date, dispersion of graphene in water-based systems has been problematic, causing coating instability or requiring large amounts of surfactant. A breakthrough technology has been developed that enables easy dispersion in water-based coatings while delivering improved corrosion performance. This development provides an important step to raising waterborne coatings’ anticorrosion performance and use.

INTRODUCTION

The development of solvent-based epoxy primer systems utilizing graphene nanoplatelets that demonstrate increased performance life1 has previously been reported. It has been demonstrated that GNPs, when incorporated into an organic coating system, provide a highly tortuous pathway that acts to impede the movement of corrosive species toward the metal surface2, a passive corrosion protection mechanism as demonstrated by decreased water vapor transmission rates3, indicating a barrier mechanism.

Waterborne technology has seen growth as interest in products with reduced environmental impact has increased. This is evidenced by increasingly stricter environmental regulations and growing end user demand for environmentally friendly technology.

For this work, we report on the development of a stable and easily incorporated graphene dispersion together with the benefits of incorporation into a water-based primer. A major challenge to the use of graphene nanoplatelets is their dispersion and stabilization. GNPs, in presenting a significant surface area, pose a challenge to colloidal stability and aggregation. Electrostatic or steric mechanisms may be used to achieve stability5,6. Water poses a challenging environment for dispersion given the low chemical functionality, hydrophobicity and large surface area of graphene.

We report an assessment of anticorrosion performance using a stabilized aqueous GNP dispersion in a water-based epoxy paint, using complementary techniques: neutral salt spray testing (NSS) and electrochemical AC impedance spectroscopy (EIS).

EXPERIMENTAL PROCEDURE

Dispersion Development and Testing

Stabilization of a colloid in water may be achieved through non-covalent modification of GNPs by use of surfactants. Several studies have been carried out on the effectiveness of surfactants.5,6,7 Insufficient stabilization may result in coagulation or aggregation of the paint, whereas too high a level may result in water sensitivity.

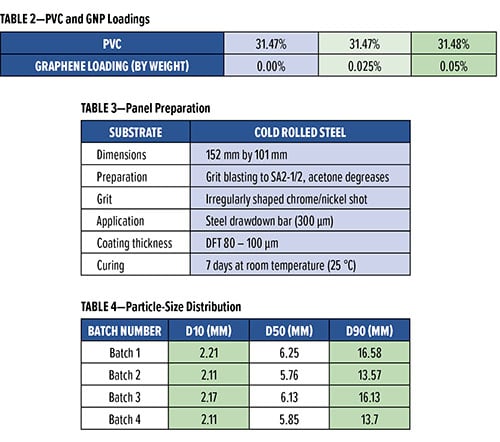

The authors have developed a resin-supported stabilized dispersion with a graphene loading of 0.5% by weight. This aqueous dispersion has reproducible quality with excellent stability and shows no agglomeration or sedimentation effects. Four batches were manufactured, with repeatable density, viscosity, and particle-size distribution, which are reported in the Results section of this article.

Material & Sample Preparation

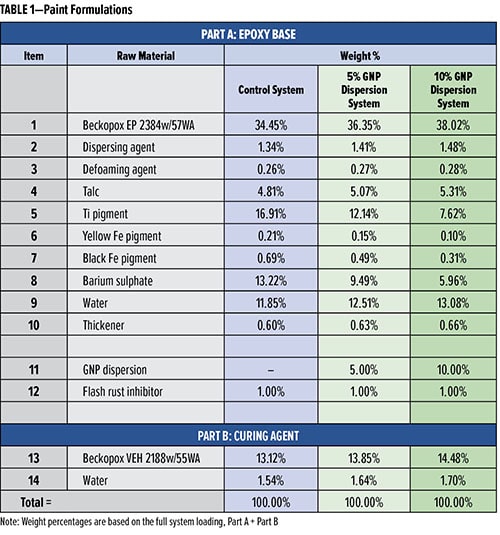

GNPs containing prototype primer formulations are detailed in Table 1. The three formulations were adjusted for PVC equivalency. Full panel preparation details are shown in Table 3.

PVC was maintained at a similar level by reducing the levels of coloring pigments and filler (titanium dioxide, red and black iron oxide, and barytes). The level of talc was left at roughly the same loading (~5%) as this is a platelike pigment which can contribute to the barrier properties of the coating. All systems were maintained at a stoichiometry of 75% (amine: epoxy). Paints were manufactured using a high-speed disperser.

A range of tests were carried out to determine suitability of the graphene modified water-based primers for use as anticorrosive primers, including:

- Neutral Salt Spray (NSS)—ISO 9227

- Electrochemical Impedance Spectroscopy (EIS). All electro-

chemical measurements were recorded using a Gamry 1000E potentiostat in conjunction with a Gamry ECM8 multiplexer.

In terms of dispersion characterization, the dispersions were made using the following methods:

- Particle size analysis determined using differential light scattering

- Viscosity as measured by a Kinexus Rheometer

- Storage stability characterized using a Turbiscan® Lab Expert stability analyzer

RESULTS

Dispersion Particle Size

Four batches were manufactured to assess reproducibility and quality of the aqueous GNP dispersions. Particle size is monitored using differential light scattering (DLS) to obtain information on how well dispersed the platelets are within the matrix, as shown in Table 4 and Figure 1. Figure 2 demonstrates monomodal distribution while the lateral dimensions of the platelets are in the micron scale, the GNPs are typically 3 to 6nm thick.